The THERMOCUBE™ is constructed from interlocking, 60mm polyurethane foam sandwich panels. The tank components are shipped as a compact kit for on-site assembly. This allows the tanks to be assembled in difficult to access areas.

BASIC PRINCIPLE: The stored, heated water never leaves the tank and the potable water, at regulated mains pressure, passes through purpose-made 316L stainless steel heat exchangers which are suspended into the hot water within the tank. Energy is transferred from the stored body of water through the heat exchanger wall to the potable supply. This heated sanitised water is then available for distribution.

- It is an extremely versatile and flexible junction point for numerous energy sources such as Solar Thermal, Heat Pumps, Gas heating, Heat recovery etc.

- Saves space in a plant room due to its flexible and adaptable rectangular design

- The tank is shipped in compact kit form. It is easy to transport, and all components fit through a standard doorway

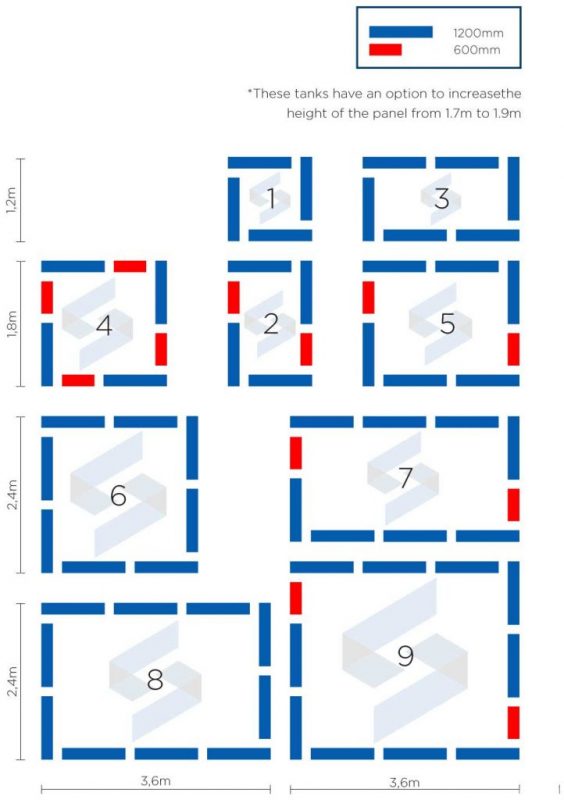

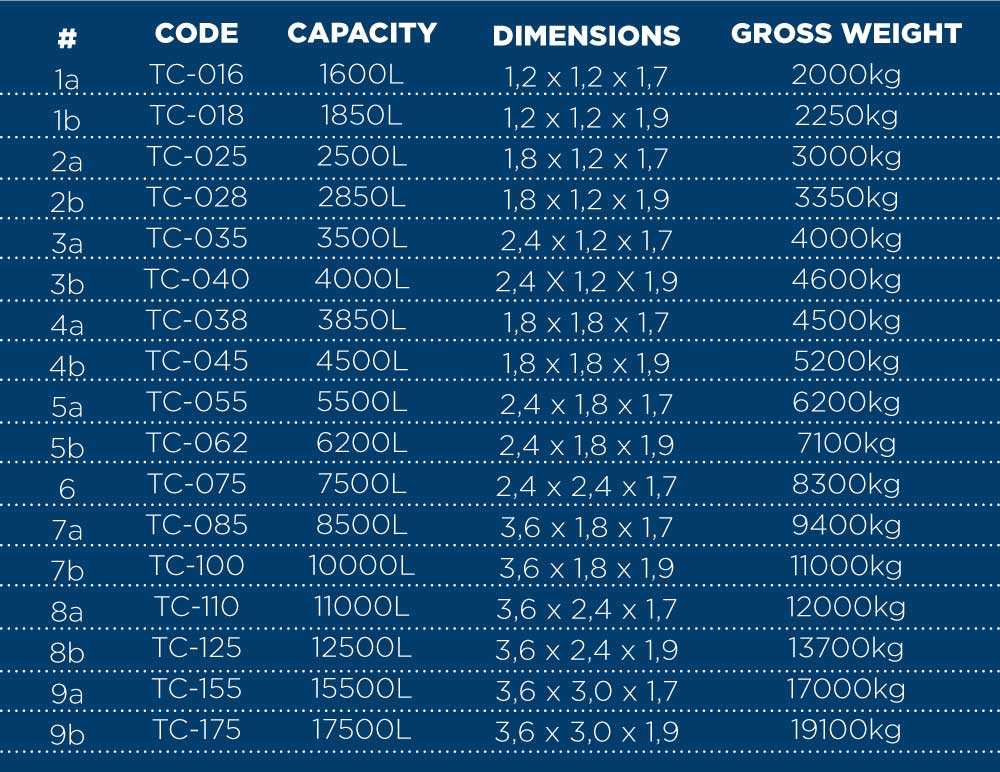

- Large range of standard sizes

- The tank is assembled on site

- Quick manufacturing time

- The spiral 316L stainless steel heat exchangers provide exceptional heat transfer, hygiene protection and corrosion resistance

- The hot water is stored at atmospheric pressure and never leaves the tank

- High level of water sanitation.

- Only fresh sanitised municipal water is fed into the hot water reticulation piping system

- Designed for outdoor applications

- Outstanding insulation properties with minimal heat loss

ENERGY EFFICIENCY

The panels are constructed from 43 kg/m3 polyurethane, foamed between 2 Chromadek sheets. The unique patented panel design eliminates temperature “bridging” and gives the tank outstanding strength and insulation properties with an R-value of >2.65 The heat exchangers are fabricated from 316L stainless steel spiral corrugated tubing with 0.3mm wall thickness which provides exceptional heat transfer properties. The large bore tube provides the necessary surface area to afford exceptional efficiency with a low water pressure drop. These heat exchangers have a maximum operating pressure of 10 bar.

ALTERNATIVE HEAT SOURCE

Superb junction point for combining different heat sources like solar panels, waste heat, heat pumps, gas etc. Perfect storage solution for low pressure drain back solar systems.

HYGIENE

The THERMOCUBE™ system maintains a high water hygiene level by separating the storage water from the potable sanitised water. Legionella and bacteria growth is virtually eliminated in this indirect system. Fresh sanitised municipal water is fed directly into the hot water heat exchanger system with a first in first out principle. The smooth shiny inner tube surface resists limescale and sludge deposits. The corrugated spiral design causes the water to vortex and agitate. This increases the heat exchanger efficiency and reduces the possibility of the build-up of solids. Deposits of limescale, sediments, sludge and rust can accumulate in traditional steel pressurised tanks. This can become a breeding ground for bacteria. This is not possible with the THERMOCUBE™ system. Heat pumps can be used without the possibility of cross contaminating the water with oil and refrigerant from the refrigeration system.

EXCEPTIONAL CORROSION RESISTANCE

The heat exchangers are fabricated from heat-treated 316L stainless steel spiral tubing. This grade of stainless steel has an exceptionally high resistance to corrosion, pitting, and crevice corrosion in chloride environments. Bulkhead fittings and supply and return headers are grade 316 Stainless steel.

TANK AT ATMOSPHERIC PRESSURE

The hot water is stored and heated at atmospheric pressure, preventing a possibly explosive situation and the need for pressure safety controls and expensive preventive maintenance measures.

LIFE SPAN

The THERMOCUBE™ stores water at atmospheric pressure eliminating the stresses of expansion and contraction associated with pressurized tanks. The THERMOCUBE™ is fitted with an EPDM rubber geomembrane liner that is flexible, resists temperature shocks and is puncture resistant. The liner is easily repairable or replaceable. All components of the tank can be individually replaced.